TORTUS II

FLOOR FRICTION TESTER Latest Model Tortus 3 PDF

FEATURES

Measurement of dynamic coefficient of friction, "u"

Microprocessor controlled

Digital readout

Integral printer

Mains and battery operation

Portable

Adjustable measurement length

Meets ISO and EU testing requirements

Easy to operate

Simple and unique

APPLICATIONS

Assessing floor safety

Evaluation of floor cleaning materials

Checking effectiveness of maintenance materials

Accident investigations

Evidence for litigation purposes

BACKGROUND

Slipping, Tripping and Falling (STF) accidents account for a significant proportion of the accidents that occur at work, in public places and in the home. Various guidelines have been produced for assessing the slip resistance of pedestrian surfaces and detailed testing requirements have been specified recently by theEuropean Union, the International Standards organisation and in a new Australian/New Zealand standard. Tortus II meets the requirements of the test methods specified and is able to provide valuable data for determining whether a particular flooring material is safe and fit for purpose.

DESCRIPTION

Tortus II is a microprocessor controlled precision instrument, which measures directly the dynamic coefficient of friction, u as it traverses a surface or flooring material to be used by pedestrians. It provides an instantaneous reading of u on a digital display as it moves across the surface and displays the average value of, u at the completion of the test. A hard copy of the measurements made during the traverse is also available from an integral printer. The unit can be mains or battery operated.

Tortus II has been developed from the earlier Tortus floor friction testers which were originally designed by British Ceramic Research Limited (Ceram Research).

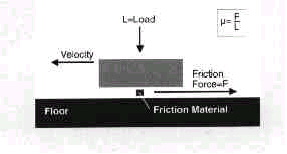

SCIENTIFIC BASIS OF MEASUREMENT

A friction slider mounted on a leaf spring assembly is held in contact with the surface under a fixed load. As the instrument moves forward ata constant velocity, the friction force deflects the slider and this is measured by a strain gauge attached to the spring assembly.

The slider area, loading and standard friction material were chosen following observations obtained by filming people walking and running

; it was shown that the most dangerous type of slip occurs when the heel slides forward on making contact with the ground. Tortus II reproduces the conditions under the heel when it first touches the ground during straight walking.

CALIBRATION

Tortus II has a simple and unique method which allows the instrument to be calibrated by the operator within a few minutes. This has considerable advantages over other similar devices, which have to be factory calibrated at regular intervals.

SAFETY IMPLICATIONS

Accurate measurements indicate when remedial action is needed to help reduce the probability of a STF accident. Tortus II can be used for :

Regular checking on all floors<

More frequent checking of potential and known trouble spots, e.g. kitchens, wet floor areas, industrial process areas where frequent cleaning is needed etc.

Checking after receiving complaints

Investigation after accidents to help determine their cause

Monitoring changes in floor conditionduring service

Training staff in floor safety

Establishing appropriate standards forthe application

COST SAVINGS

Cost savings result from achieving and maintaining good floor safety standards by:

Reducing the working days lost due to STF accidents

Preventing expensive damages claims

Avoidingproduction stoppages

Assessing floor cleaning treatments to determine cost effective solutions

SPECIFICATION

Overall dimensions : 430 mm x 240 mm x 160 mm

Overall weight : 8 kg

Power requirement : 240v or 110v 50/60Hz - Internal battery 12v DC with charger

Friction foot material : 4S rubber (standard shoe simulating, developed by the Rubber and Plastics Research Association UK - RAPRA)

The instrument is supplied with a case

|