MULTIFLASH AUTOMATICPMCC, Abel, Tag, Cleveland & Setaflash Flash Point Tester

SPECIFICATION The instrument comprises a universal base unit that houses the display, control and data acquisition functions, and a series of interchangeable modules that allow the performance of the required standard test methods. MultiFlash is ruggedly designed to provide simple and reliable operation and is specifically engineered to ensure a very low cost of maintenance.

CHARACTERISTICS

34000-0 'MULTIFLASH' Automatic PMCC, Abel, Tag, Cleveland & Setaflash Flash Point Tester Flash Point, Smoke Point and Sustained Burning Multi Method Flash Point Tester EASE OF OPERATIONMultiFlash operation is microprocessor controlled, and a backlit alphanumeric / graphics display and control panel provides a simple user interface using 2 buttons and the Multifunctional And Rotational Test (SMART) control feature. The SMART control is exceptionally easy to use for setting modes of operation, temperatures, parameters and calibration.

PRECISE TEST RESULTSPlatinum Resistance Thermometers are used exclusively throughout MultiFlash to ensure accuracy, reliability and robustness. Verification or re-calibration of all instrument parameters is simple but secure.

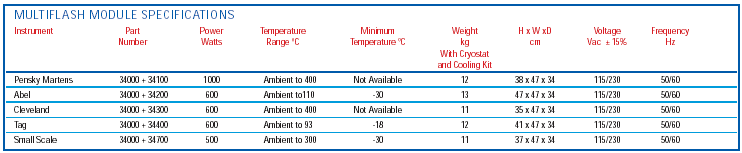

WIDE TEST TEMPERATURE RANGEElectrical heating provides precise and reliable test temperatures for all modules. An integral cooling fan assists in preparing the instrument for the next test. Some modules also allow the use of an external coolant supply to enable sub ambient test temperatures, and to provide a fast cool down facility at the end of the test.

INTERCHANGEABLE TEST MODULESMultiFlash test modules faithfully conform to the requirements of the appropriate test method. Changing the test module is straightforward and completed within a few minutes. The module locates into an intelligent base unit, that recognizes the module type and automatically sets up relevant test parameters and calibration data. Each module includes a DIPS pod (Dipping, Ignition, Pilot, Stirrer) containing the ignitor dipping mechanism, the gas and electric ignitors, the electric ignitor pilot, and a stirrer (if required by the test method).

GAS OR ELECTRIC IGNITION OPTIONSElectric Hot wire or gas ignition sources can be selected from the control panel for all tests and modules. The unique quick-fit coaxial ignitor comprises a gas jet in conformance with the requirements of the test method, and an electric hot wire, which also ignites the gas jet when required. The ignitor is simple to change, low cost, and has a long service life. For electric ignition the instrument uses precision electronic control to ensure that the hot wire provides a constant ignition temperature and to prevent premature failure. For gas ignition, an electrically controlled valve automatically switches the gas supply on, and the gas jet is ignited by the electric hot wire. An integral rechargeable butane canister is supplied, however provision is made for the use of an external gas supply if required.

AUTOMATIC FLASH DETECTIONAutomatic flash detection for the closed cup modules is achieved using thermocouple technology which has proven to be most effective for all products including bio-diesels and those containing moisture. The Cleveland module is fitted with an ionising ring flash / fire detector that has been universally proven and adopted for this open cup test.

SIMPLE CONTROL FUNCTIONSAt the beginning of the test the test sample is placed in the cup / lid assembly. The DIPS pod is brought into mechanical contact with the cup / lid assembly by a simple push to engage operation. A simple start control initiates the test and the status is continuously monitored with any problems or error conditions being shown on the display.

AUTOMATIC RESULTAt the end of the test the DIPS pod is automatically disconnected from the cup, the display shows the result, an audible warning is given and the cup and associated heating system are cooled down to a user defined temperature.An integral electronic barometer automatically corrects the flash point value in accordance with the mandated equation that is included in all flash point methods. The result and key test parameters are shown on the display and may be transferred via an integral RS232 interface to a printer or external computer.. When connected to a printer the test report includes a sequential test number and identification. The last test result is stored in the instrument and may be accessed from the control panel. The SETALERT radio paging accessory can immediately alert the operator of the end of the test or an operational problem.

INTEGRAL DRAUGHT SCREENA full height transparent draught screen is provided with each module and is rotated into the required position. The screen assists in obtaining consistent and accurate results even when the MultiFlash is used in air conditioned laboratories or under a fume hood. The screen also functions as an operator safety screen.IN-BUILT SAFETYIn the event of instrument over-temperature 3 independent safety systems are automatically activated. The power supply to the heating elements is isolated, the gas supply to the ignitor is shut off, and the cooling fan is switched on to reduce the cup temperature.

RELIABLE OPERATION AND EASE OF SERVICEMultiFlash is designed to provide long and reliable operation. Maintenance requirements are limited to replacement of service components, such as the igniter, which is inexpensive and quickly fitted.SUPPLIED WITH: mains lead and instruction manual

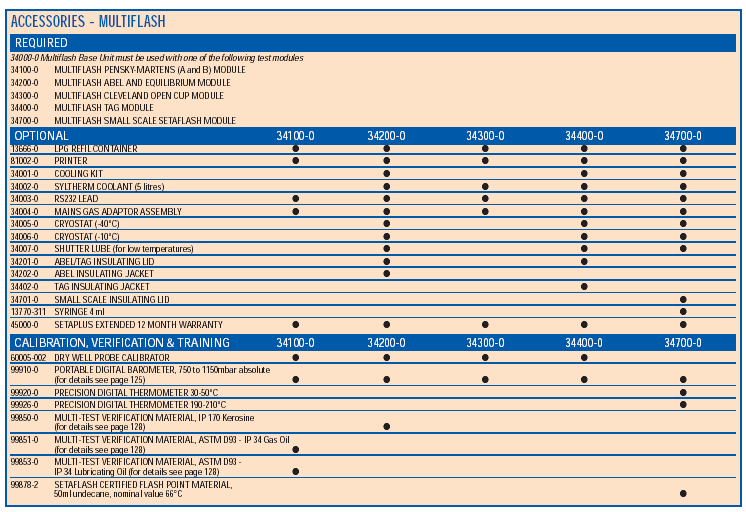

Multiflash Models |