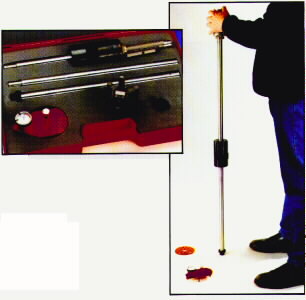

BRE SCREED TESTER

Measures Screed Soundness as early as 14 days after laying

Description

Dense floor screeds which on visual

inspection appear to be sound, i.e.able

to withstand imposed loads and traffic,

may in fact be sub-

standard.Specifications often state that

the cement /sand screed should be

semi-dry, a consistency which when

manually compressed may result in the

lower layers being insufficiently

compacted. This may cause the screed

to fail under the impact of heavy traffic

or furniture movement. Subsequent

remedial work on the screed is often

costly and time consuming.

The tester is designed to measure

screed soundness as early as 14 days

after laying. The device consists of a

Im long, cylindrical guide rod, along

which an annular weight of 4 kg travels

when released. At the bottom of the

guide rod the weight strikes the collar

of a case-hardened steel anvil which

transmits the impact to the selected

area of the screed.

Research has shown that four

successive impact blows on the same

spot are sufficient to test the soundness

of the screed. Any area where the

impacts produce an indentation of

3 mm or less can be considered sound,

according to current data. Where the

indentations are greater than 5 mm the

screed is considered and may fail when

in use. BS8203 gives guidance on the

type of use of a floor and its associated

acceptance limits after four drops of the

weight. The depth of indentation is

measured with a purpose-made

mechanical gauge or a more

sophisticated direct-reading digital

electronic gauge which is available if

required.

Specification

Drop weight = 4 kg

Drop height = 1000 mm

Contact area of anvil 500 mm2

Overall dimensions

of carrying case 515x375x125 mm

Weight of BRE screed

tester in case 9.75 kg

|