Espa�ol

Wheel tracker EN12697-22 Large device

CRT-WTEN � CRT-WTEN1 & CRT-WTEN2

Wheel tracking is used to assess the resistance to rutting of asphaltic materials under conditions which simulate the effect of traffic. A loaded wheel tracks a sample under specified conditions of load, speed and temperature while the development of the rut profile is monitored continuously during the test. Test specimens can be either slabs prepared with a laboratory compactor or 200mm diameter cores cut from the highway.

The CRT-WTEN1 wheel tracker performs both of the test methods that are specified for a small scale device in EN 12697-22. It is likely that the procedure B from this standard will be the test method of reference. It is considered to be more accurate as it measures rut depth at 25 points along the wheel path. As a consequence, only two specimens need to be tested to represent one material. With this approach in mind, we have developed the CRTWTEN2 which tests two specimens simultaneously with the advantage of totally identical test conditions.

FEATURES

� User friendly Windows software

� Integral temperature controlled cabinet

�Test temperature range 30�C to 60�C

� Tests for specified number of passes or to specified rut depth

� Double glazed doors for viewing test

�Conditioning of specimens at test temperature

� Automatic test stop/start and speed control

� Supplied with UKAS accredited calibration

� Specimens can be compacted in Roller Compactor and then wheel tracked without demoulding

� Can be supplied to conform with EN 12697-22, BS 598, or AST 01:2004

The CRT-WTEN can be used for:

� The identification of rut-susceptible mixtures so that expensive remedial works are avoided.

� The evaluation of new materials and formulations.

� Studying the effect of level of compaction (void content and mixture density) on resistance to rutting.

�Validating mix designs.

SYSTEM ELEMENTS

The CRT-WTEN1 comprises a solid extruded aluminium frame supporting a PID controlled temperature cabinet made from stainless steel and fitted with double glazed doors for full access. The test specimen is mounted on a table which is reciprocated a distance of 230mm on linear bearings at the specified speed. A loaded rubber tyred wheel runs on top of the specimen and the resultant rut is monitored as the test proceeds using a calibrated displacement transducer. The equipment is controlled and the test data acquired, via an interface unit, using the test software supplied.

The software automatically starts the wheel tracker, maintains the speed at the required level, measures rut depth and sample temperature, provides a continuously updated on-screen graph of rutdepth versus time and stops the wheel tracker when the test is finished. On completion of a test the rate of rutting is calculated and a test report can be printed using the supplied software. If required, the stored test data can be analysed and compared with other test data using a spreadsheet.

The CRT-WTEN2 reciprocates two specimens. It is larger than the CRT-WTEN1 and there is user access from both sides of the machine.

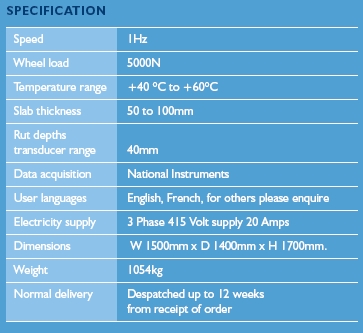

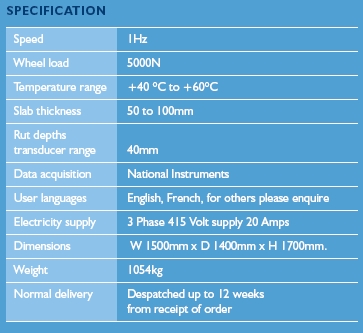

We also produce the Large scale wheel tracker specified in EN12697-22 and EN13108-20, please enquire for details.

See also:

The Wheel tracker

Hamburg Wheel tracker

Wheel tracker Large device

NAT Asphalt Testing System

Universal Servo-Pneumatic Test System

Universal Servo-Hydraulic Test System

Four point beam fatigue test

Roller Compactor

Roller Compactor Large device EN